Is there a quick way to learn if these values are the best I can do on a SoCal project without adding cost to a project?:

Hello - It’s difficult to know how much lower you can go without more detail on the project. Placement methods (CIP through a tailgate vs pumping, shotcrete, pile foundation mixes, etc.) have a significant impact on the proportions of paste in the mix, which can significantly change the GWP. If the project has a high volume of concrete that can accommodate higher cement replacement without impact on the schedule and finishing time, then lower values could be realistic. It also depends on if you intend every mix to be below these GWPS or if you plan to use them to set an entire project goal based on volumes for each strength. I work for Vulcan Materials and we supply aggregates to ready-mixed suppliers in Southern CA and we are a concrete supplier in San Diego as well. Feel free to reach out if you want to discuss further or if we can be a resource on estimating cost-neutral options for the lowest GWP of particular projects.

Thank you - Most of the concrete is CIP piles, pile caps, and slab on grade.

Ah, I see. In that case I find it most beneficial to work with the local suppliers or anyone else in that market who has data on pile mixes to develop the typical GWPs associated with that type of mix. I’ve done that analysis in the SF Bay Area where we supply concrete to compare those GWPs by PSI to the GWPs of CIP mixes. Auger cast mixes will probably have the highest GWP for the project since they usually have a higher paste content. The pile caps could probably go lower than the 85% value. Slab on grade mixes usually aren’t as low in GWP as pile caps due to needing a reasonable set time for finishing, so the 85% value might be more accurate in that case.

If you can’t get a hold of suppliers (although most are willing to talk to you so hopefully you won’t get too much push back) another resource is to skim through EC3’s database and filter by location. It might be challenging to really know if the mix is comparable for the applications you need but it does help narrow down the GWP by region from just being “NRMCA pacific southwest” to “California” and likely even southern California.

@aaron.vaden-youmans I am happy to say that we have a tool for this on our website! The tool takes the data from EC3 and allows you to visualize local product EPDs and their GWP’s graphically. Take a look and let me know what you think!

We have found that, depending on the requirements for your particular mix besides strength (set time, etc), the “best practice” numbers have been achievable targets without too much of a cost premium, where as the “min” values start to have more of a cost premium. The values from EC3 does not differentiate mix type by component though.

Thank you John,

This is great. I am further socializing it with our wider project team. So, you’ve found that, depending on the requirements for the particular mix besides strength (set time, etc.), the “best practice” numbers have been achievable targets without too much of a cost premium, whereas the “min” values start to have more of a cost premium. Why is that? What are the factors that are driving those costs?

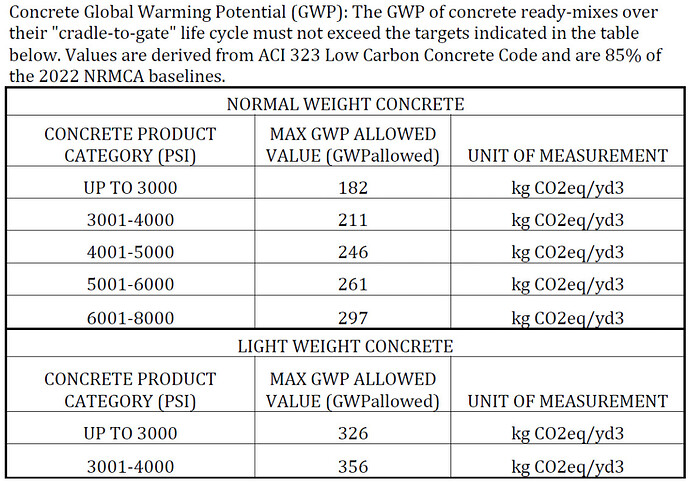

Does this table track with your understanding:

Lower embodied carbon concrete targets - e.g., 50%+ below baseline - may attract cost premiums in the U.S. for several key reasons, even though some reductions are cost neutral. These premiums generally arise from material, process, supply chain, and market dynamics.

Summary: Why Premiums Exist

Reason

|

Explanation

|

- | - |

Performance adjustments

|

High-strength or fast-setting mixes may need more expensive admixtures

|

Material scarcity

|

SCMs like slag/fly ash are limited and in high demand

|

Market immaturity

|

New low-carbon technologies aren’t yet cost-competitive

|

Testing & QA

|

Owners/specs often require additional EPDs or validations

|

Risk pricing

|

Contractors/suppliers bake in costs for unfamiliar or non-standard mixes

|

Your input here is really appreciated.

Regards,

Aaron

|

Aaron Vaden-Youmans T +1 323 471 6700 |

|||||||||||

This transmission is intended solely for the person(s) to whom it is addressed and may contain confidential information. If you are not the intended recipient of this transmission, please send it back to us and immediately and permanently delete it from your system. Do not copy, use or disclose the information contained in this message or in any link or attachment. You must not, in any way, infringe the design and intellectual property rights of Grimshaw. Risks are associated with sending information by email including interception, amendment, loss and delay, as well as the transmission of computer viruses. Although Grimshaw has taken reasonable precautions to reduce such risks, any person communicating with Grimshaw by email will be deemed to have accepted the risks and Grimshaw disclaims all responsibility which arises directly or indirectly from the use of email communication. For information about how we process data and monitor communications please see our privacy policy.

@aaron.vaden-youmans cost can get very tricky the more you get into it. If you are trying to create a uniformly applicable formula for predicting how cost may be impacted by GWP target, I don’t have a good answer for you. The important thing as Alana alluded to, is early communication between design team, GC, and concrete supplier to make sure the most cost and GWP efficient mixes can be procured based on application type and availability of various ingredients.

Thanks. Yes, I agree with that. What language have you put into specs that support that type of process? For example, have you put both limits and targets with a description of a process for achieving the lowest GWP concrete without attracting costs?

|

Aaron Vaden-Youmans T +1 323 471 6700 |

|||||||||||

This transmission is intended solely for the person(s) to whom it is addressed and may contain confidential information. If you are not the intended recipient of this transmission, please send it back to us and immediately and permanently delete it from your system. Do not copy, use or disclose the information contained in this message or in any link or attachment. You must not, in any way, infringe the design and intellectual property rights of Grimshaw. Risks are associated with sending information by email including interception, amendment, loss and delay, as well as the transmission of computer viruses. Although Grimshaw has taken reasonable precautions to reduce such risks, any person communicating with Grimshaw by email will be deemed to have accepted the risks and Grimshaw disclaims all responsibility which arises directly or indirectly from the use of email communication. For information about how we process data and monitor communications please see our privacy policy.

We just put a GWP target in our specs. We try to have discussions with suppliers before the specs are finalized to ensure the target we list can be met, and further optimization hopefully takes place after specs are finalized. Obviously varies by project.